Introduction

GH2901(GH901) is an austenitic aging lymphoma alloy based on Fe-43Ni-12Cr, with titanium, aluminum and strengthening elements added. It also contains trace amounts of boron and lower carbon. It is processed by metastable γ[Ni3(Ti, Al )] phase dispersion strengthening, and trace amounts of aluminum can inhibit the transformation of γ to eta-Ni3Ti phase. The alloy has relative turning strength and lasting strength below 650℃, good oxidation resistance below 760℃, and stable structure for long-term use. It is a relatively mature alloy developed in the early stage and is widely used in the manufacture of rotating disk parts (turbine disk, compressor disk, journal, etc.), static structural parts, and turbine outer rings of aviation and ground gas turbine engines operating below 650°C. and remaining spare parts.

Chemical components Chemical element composition content(%)

Composition | C | Si | Mn | P | S | Cr | Ni | Mo | Al | Ti | B | Cu | Bi | Pb |

Min | 0.02 | \ | \ | \ | \ | 11.00 | 40.00 | 5.00 | \ | 2.80 | 0.01 | \ | \ | \ |

Max | 0.03 | 0.40 | 0.50 | 0.02 | 0.008 | 14.00 | 45.00 | 6.50 | 0.30 | 3.10 | 0.02 | 0.20 | 0.0001 | 0.0001 |

Mechanical properties

Rigidity | Tensile strength | Yield strength | Elongation |

200 | ≥1034MPa | ≥689MPa | ≥12% |

Physical properties

Density | Melting points | Specific heat | Magnetism | Resistivity | Thermal conductivity | Linear expansivity |

8.4g/cm3 | 1415-1450℃ | 0.41J/(Kg.℃) | \ | 1.073Ω·mm²/m(300℃) | 12.0W/(m.k)(300℃) | 15.5×10-6/K(20-700℃) |

Availability products

Mono Group Alloy 901 is available in Flat Bar, Round Bar, Rod, Wire, Welding Wire and Forging Stock.

Product type | Products | Dimension | Processes | Deliver Status |

Plates / Sheets | Plates / Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

Coil / Strip | Steel Coil /Steel Strip | 0.03-16.0x1200mm | Cold-Rolled & Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

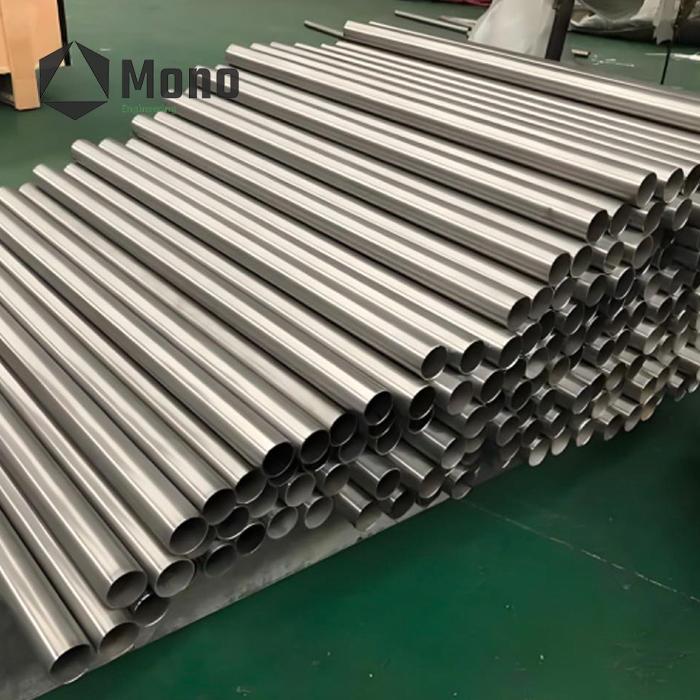

Pipes / Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |

Advantages

(1)High temperature strength: the material can maintain excellent mechanical properties at temperatures up to 980°C, and its yield strength and lasting strength can reach high levels at high temperatures.

(2)Oxidation resistance:GH2901 alloy contains higher chromium content, In high temperature environments, GH2901 can form a stable oxide film, effectively preventing oxides from further eroding into the alloy.

(3)Creep resistance:GH901 exhibits excellent creep resistance under high temperature and continuous load, and can maintain stable shape and size .

(4)Corrosion resistance:GH901 is especially suitable for environments with various chemical media such as acids, alkalis, and salts.

(5)Structural stability:the structure of GH2901 remains stable and is not prone to notch sensitivity

(6) Weldability:GH2901structure and performance are stable after welding

Applications

(1) Aerospace: aerospace engines, turbine blades, combustion chambers and nozzles due

(2) Chemical : reactors, heat exchangers, storage tanks, pipelines and other equipment.

(3) Oil and gas :used in the oil and gas industry to manufacture oil well equipment, oil pipelines and drilling tools.

(4) Nuclear energy :nuclear reactors, nuclear fuel elements and nuclear power plant equipment.

MONO Group is one of Superalloy, Nickel alloy, high Temperature alloy manufacturer&Supplier&Wholesaler from China,We can supply high quality alloy plate,sheet,round bar,tube.pipes,fittings,flange,pls contact us freely for your RFQ to info@monokj.com